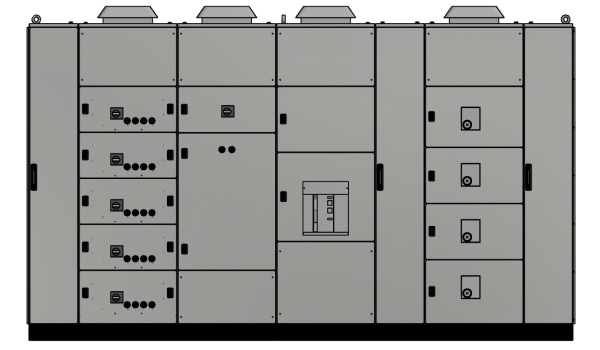

LV & MV Switchgear Production + Compact Secondary Substations

Type-tested, seismically verified and form-based switchgear solutions.

The team behind Netral Industrial Group has been designing and building LV & MV switchgear since 1998. Today, our focus is not on simply filling enclosures with devices, but on delivering type-tested, seismically verified and IEC form-compliant switchgear platforms.

Type-tested switchgear

Our designs are based on type-tested principles in line with the relevant IEC standards:

-

For LV panels, the IEC 61439 series (covering temperature rise, short-circuit withstand, IP protection, mechanical strength, etc.)

-

For MV switchgear, the IEC 62271 series (covering dielectric performance, short-circuit and internal arc withstand, among others)

This means that the core switchgear design is backed by laboratory-tested performance in terms of thermal behaviour, short-circuit withstand, degree of protection and mechanical integrity. Every delivered panel belongs to this validated design family, rather than being a one-off assembly.

Seismic performance

For power plants, hospitals, data centres and critical infrastructure, seismic behaviour has become a key part of the specification. In this context:

-

Our switchgear structures are modelled according to seismic test-verified design principles

-

Centre of gravity, anchoring pattern and cabling interfaces are engineered with dynamic forces under earthquake conditions in mind

-

When requested, we provide seismic test reports and calculations as part of the technical dossier

The goal is not only to keep the panel standing, but to maintain operability during and after a seismic event.

Form-based designs (Form 2, Form 3, Form 4)

To ensure operational continuity and safe maintenance, IEC form of separation has become an important requirement in many projects. We therefore:

-

Design and deliver panels in Form 2, Form 3 or Form 4 configurations depending on the project needs

-

Use compartmentalisation between busbars, feeders and control sections to localise faults and protect maintenance personnel

-

Apply form-compliant partitioning, door systems and interlocks aligned with IEC guidance

This approach transforms a potential single-point failure into a controlled, compartmentalised event that does not take the entire installation down.

Compact Secondary Substations (CSS)

Our compact secondary substation (CSS) solutions integrate MV switchgear, a distribution transformer and an LV panel into a single, factory-assembled enclosure. According to IEC 62271-202, these are prefabricated, type-tested transformer substations intended for outdoor use in public distribution networks, typically up to 52 kV.

Each CSS is engineered as a three-compartment design:

-

MV compartment – RMU or AIS switchgear for incoming and outgoing feeders

-

Transformer compartment – oil-immersed or dry-type transformer with proper ventilation and earthing

-

LV compartment – main LV switchboard, protection, metering and optional reactive power compensation

Built in line with IEC 62271-202 and related IEC/EN standards, our CSS units are:

-

Compact in footprint, yet fully accessible for operation and maintenance

-

Designed for safe public-area installation with the right IP class and internal arc classification

-

Pre-engineered for fast deployment in urban networks, industrial plants and renewable energy projects

How we deliver

Across our type-tested, seismically engineered and form-based switchgear and CSS line, you can expect:

Engineering-led design

-

Single-line and load list review

-

Selectivity and coordination studies, short-circuit and load-flow-based sizing

Standards-based documentation

-

Type test references and routine test protocols aligned with relevant IEC standards

-

Single-line diagrams, GA drawings, cabling and interface details

-

Operation and maintenance manuals

Export-ready packaging

-

Factory Acceptance Tests (FAT) before shipment

-

Labelled, palletised and vibration-resistant packing

-

Complete technical file and certification set for international projects

If your project specifies type testing, seismic verification or a defined form of separation, our engineering teams integrate these requirements directly into the switchgear architecture from day one – not as an optional add-on, but as part of the core design philosophy.